The Solution to Premature Phone Battery Deaths.

The Roo Bag, an actively heated and insulated pouch for a phone to ensure the battery stays at an optimal temperature for all climates.

An Idea can only become a Product if it has the Business Model to back it

In the Fall of 2021, my team of five, as well as four other teams were tasked with coming up with an idea, then making the idea work, and being able to sell it as a legitimate product. We worked for 4 months to develop a product that would be ready to be manufactured and sold to consumers. This involved a fully functioning product as well as all the market research to develop a business plan.

Product Developement

-

Prototype Roo Bag

For this prototype we used neoprene because of it’s insulating properties but foud it was not water-resistant enough for our needs

-

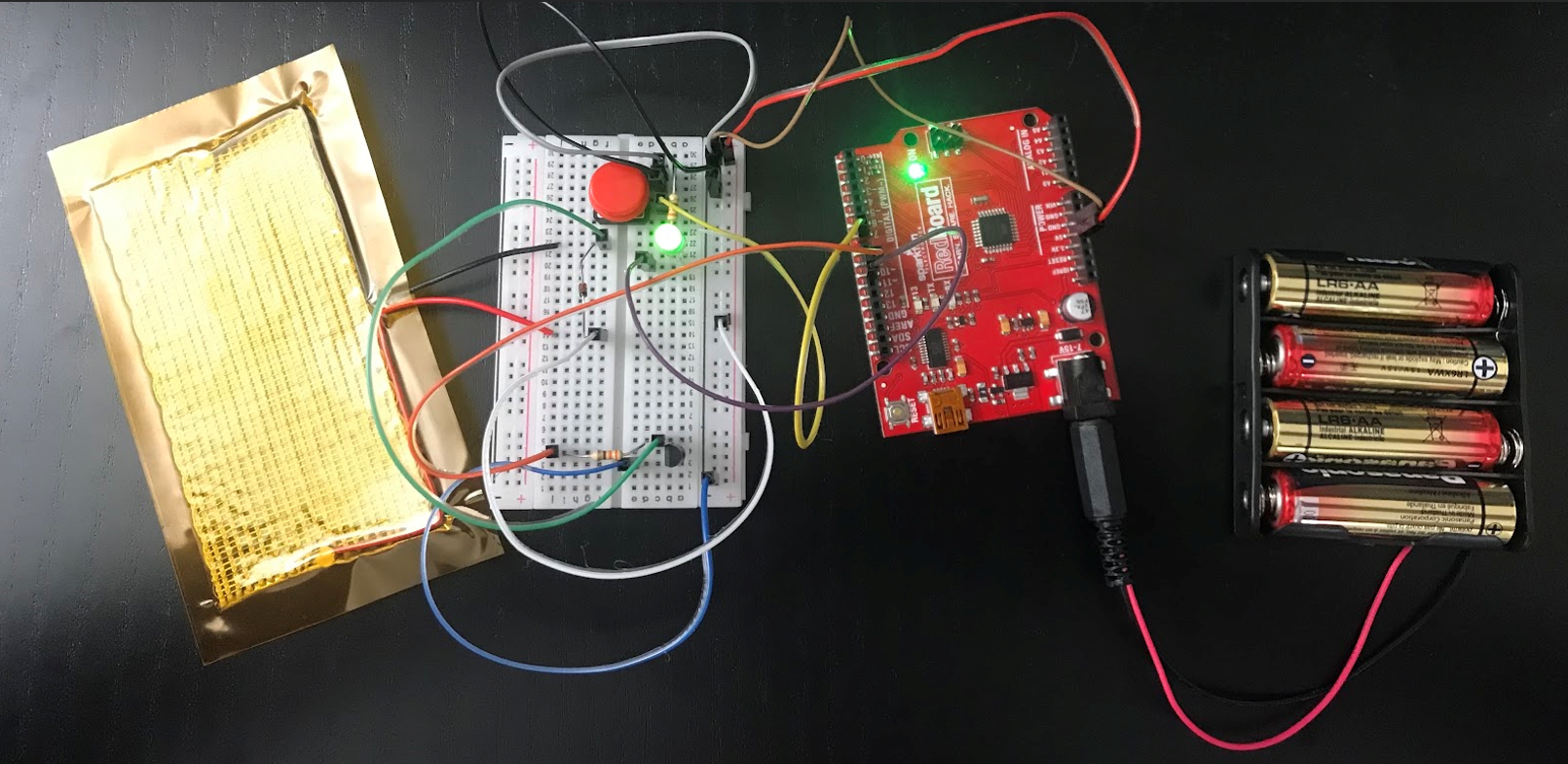

Prototype Circuitry

Our Prototype internals was running off 4 AA batteries, an Arduino Tiny, and a generic breadboard. This was meant to test the components of our circuit and the temperature hysteresis prior to miniaturization. We added an LED to indicate when the heating pad was being powered for testing purposes. The code for the temperature hysteresis was set to turn on the bag at 60 degrees Fahrenheit and turn off the heating pad at 70 degrees Fahrenheit.

-

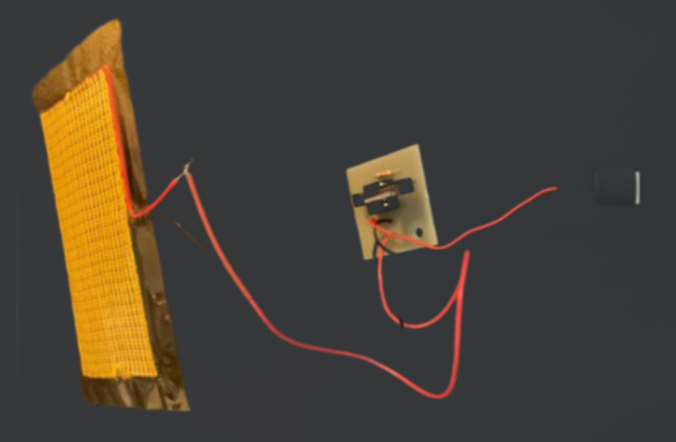

Final Ciruitry

For our final circuit, we moved to a custom PCB and an AT tiny. We also changed from using 4 AA batteries to a rechargeable portable charger. This would allow for the customer to be able to recharge the battery without having direct access to the internal components. We also changed the purpose for the LED, it was now being used to indicate when the battery was turned to indicate to the user. This LED was placed outside of the protective case so it could be seen easier by the user. In our testing, we found in the worst conditions our battery would last for six hours.

-

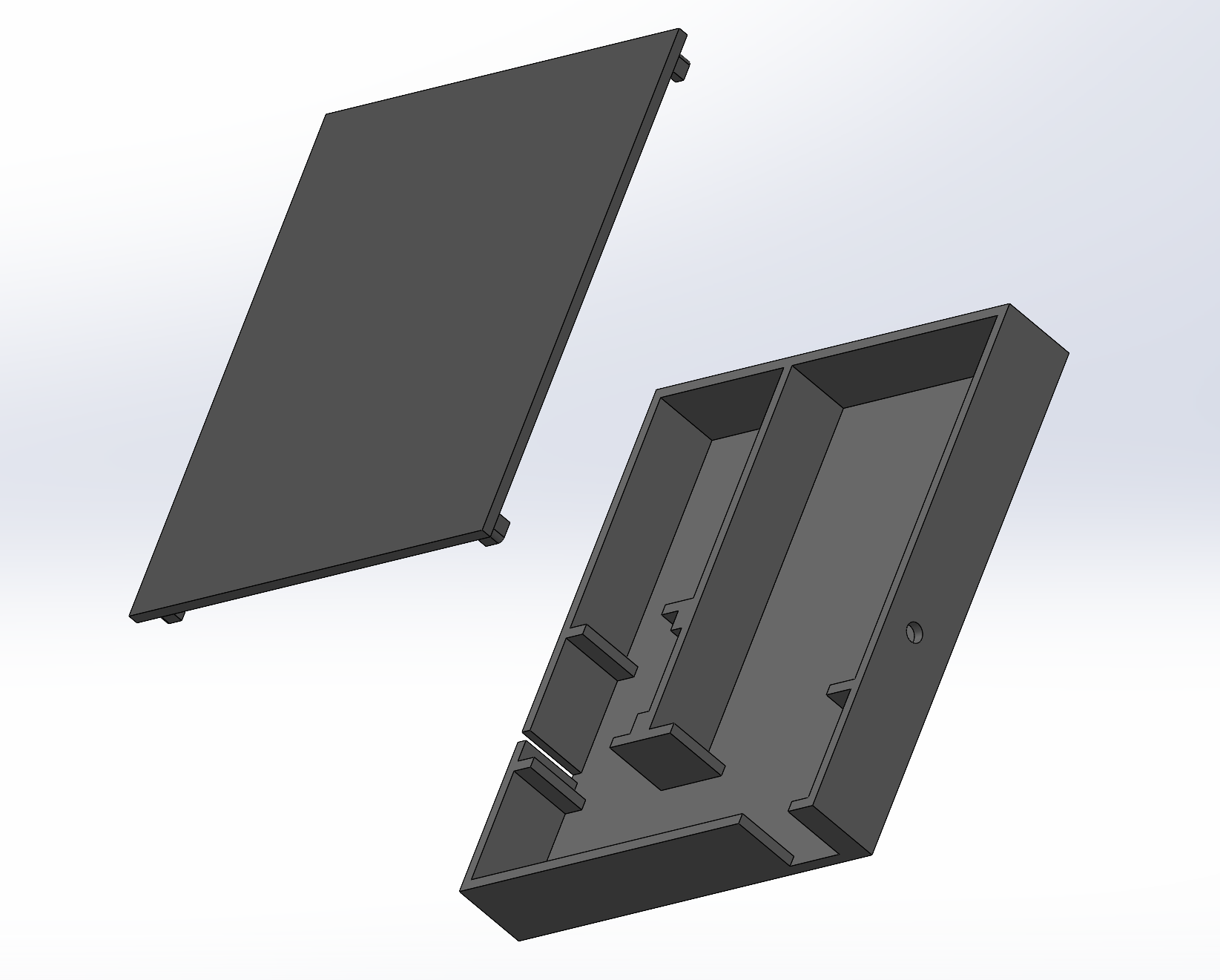

Protective Circuitry Case Mark I

Our original protective case layout fits all the components very well. Unfortunately, the case was far too wide and thicker than we desired and was unable to slide into the bag. We would redesign the case and the placement of the PCB as well as make the case to be thinner.

-

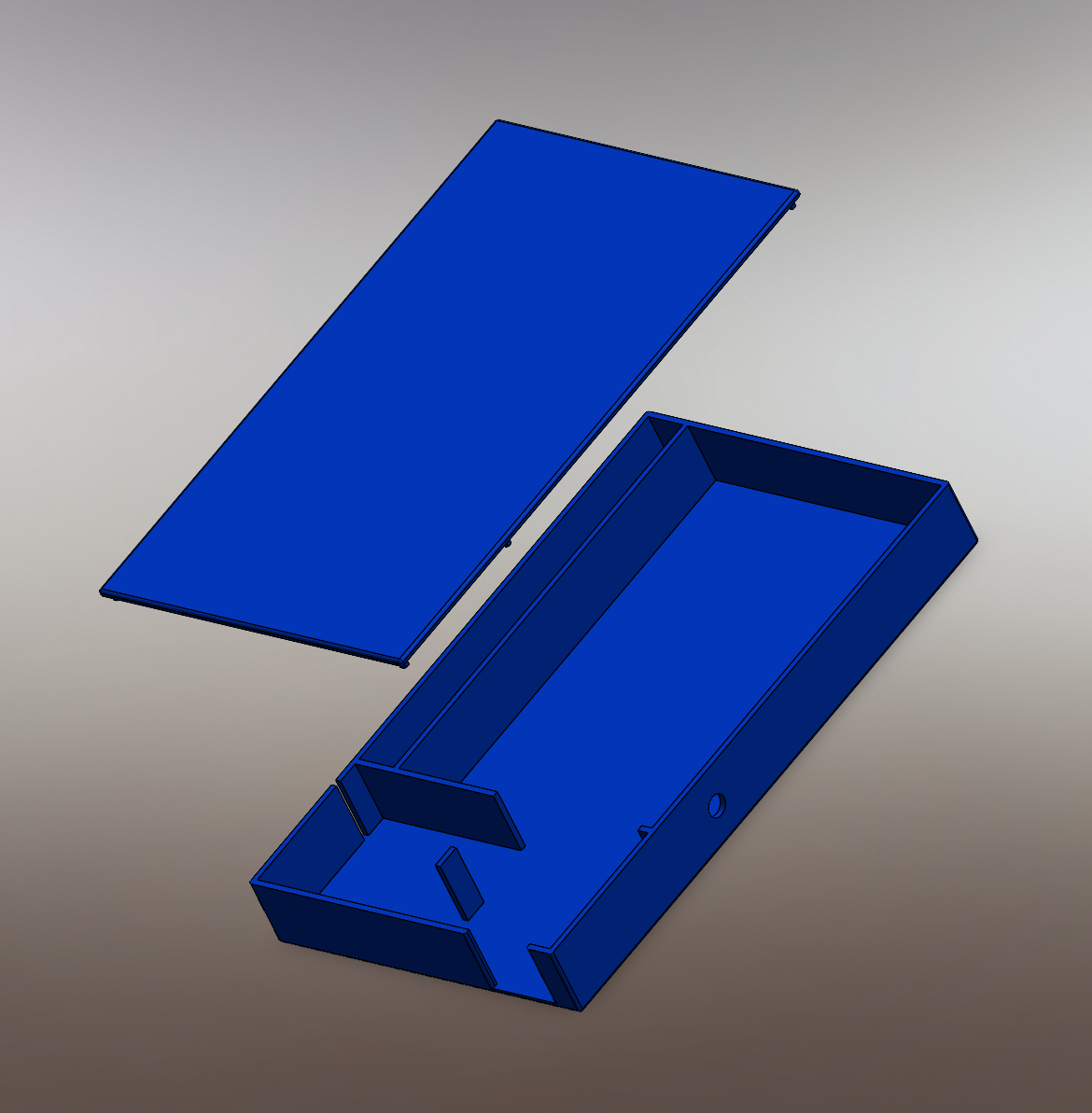

Final Protective Circuitry Case

Our Mark II protective case ended up being 6 mm thinner, and 35 mm less wide. The wall thickness was also reduced by 50% to further reduce the width and thickness. With these adjustments, the case was thin enough and more importantly, was able to slide into the bag.

-

Final Bag Design

Our final bag design changed from the exterior fabric from neoprene to polyester to be more water-resistant. We still used neoprene, but it was used as a liner along with foam to give the bag some cushion if it was to be dropped. To finish off the looks, we ironed on our Logo and power button icon.

Where Business Meets Design

Our first step of this endeavor was coming up with an idea that would fix a pain point for our potential consumers. With this idea, we took the next step of creating a pretotype, a simple non-functioning rendition of our idea that customers would mess around with and give input to. We also conducted over 120 online surveys regarding our product and the consumer’s desire for the product as well as their wants and needs for them to buy the products. We coupled this with 20 in-person interviews to clarify the pain points of a customer and what solutions they would prefer. With that information, we moved to make the prototype. While we were conducting the surveys we also researched for potential patent infringements we might encounter and need to avoid. Once we had a functioning prototype, we presented our prototype to several groups doing the same assignment to get feedback about what our product did well and still needed to improve upon. With the latest feedback, my team and I made the final adjustments and started to evaluate the business logistics. We created a breakeven analysis for the number of units we would need to sell to turn a profit to be a viable business. This calculation helped us to create our business model as well, outlining our plan to manufacture and grow the business as well as how we plan to penetrate our target market and actually sell our product. We had a final pitch presentation where we described our product and business plan to a panel of judges. The judges were encouraged to ask difficult questions to check our knowledge of our product and the market in which we were attempting to penetrate.