For the 2023 competition, the CU Boulder Formula SAE team designed our 3rd car, CB4. This was the first car that was going to be designed, manufactured, built, and tested in a single year.

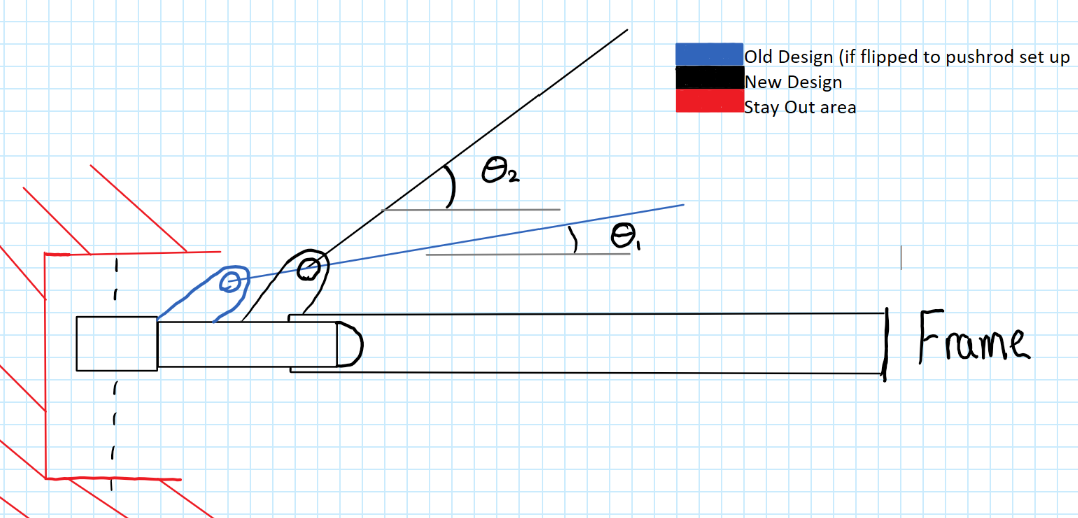

As a second-year member of the team, my part assignment was the control arms. Due to geometry changes in the front of the car, the team decided to change from a pull rod design with inboard dampers connected via a rocker, to a push rod with an inline damper mounted outboard of the car. This change was made primary for driver packaging as well as avoiding a plagued design of having the hard lines for the brakes going over the damper covers on the floor of the car.

August 2021 - June 2022 CB2/CB3

During my first year on the CU Boulder Formula SAE team, we were finishing the design for CB3 but were mainly focused on manufacturing. I learned how to manufacture parts using a lathe and mill. Since most of the design work was already complete I focused on learning about the subsystems through assembling the car.

I was invited to join the team for the 2022 Formula SEA Michigan competition. While there I was helping prep the car for static tech as well as set up changes in an attempt to pass the braking test. This time proved to be a great learning experience to see how other teams operate and see many other design ideas as well as make connections with members of teams.

June 2022 - May 2023 CB4

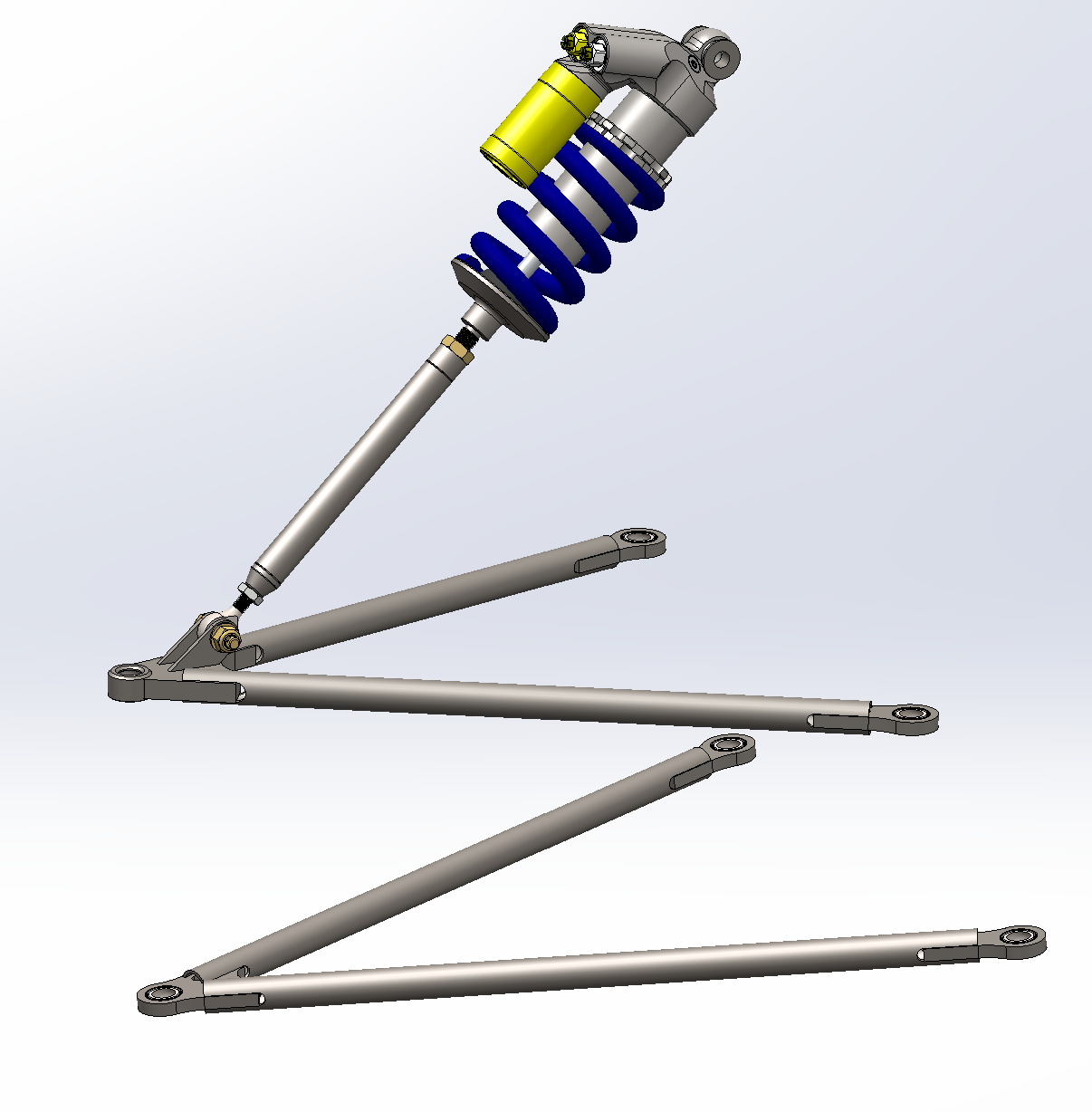

CB3 Front Control Arms with pull-rod

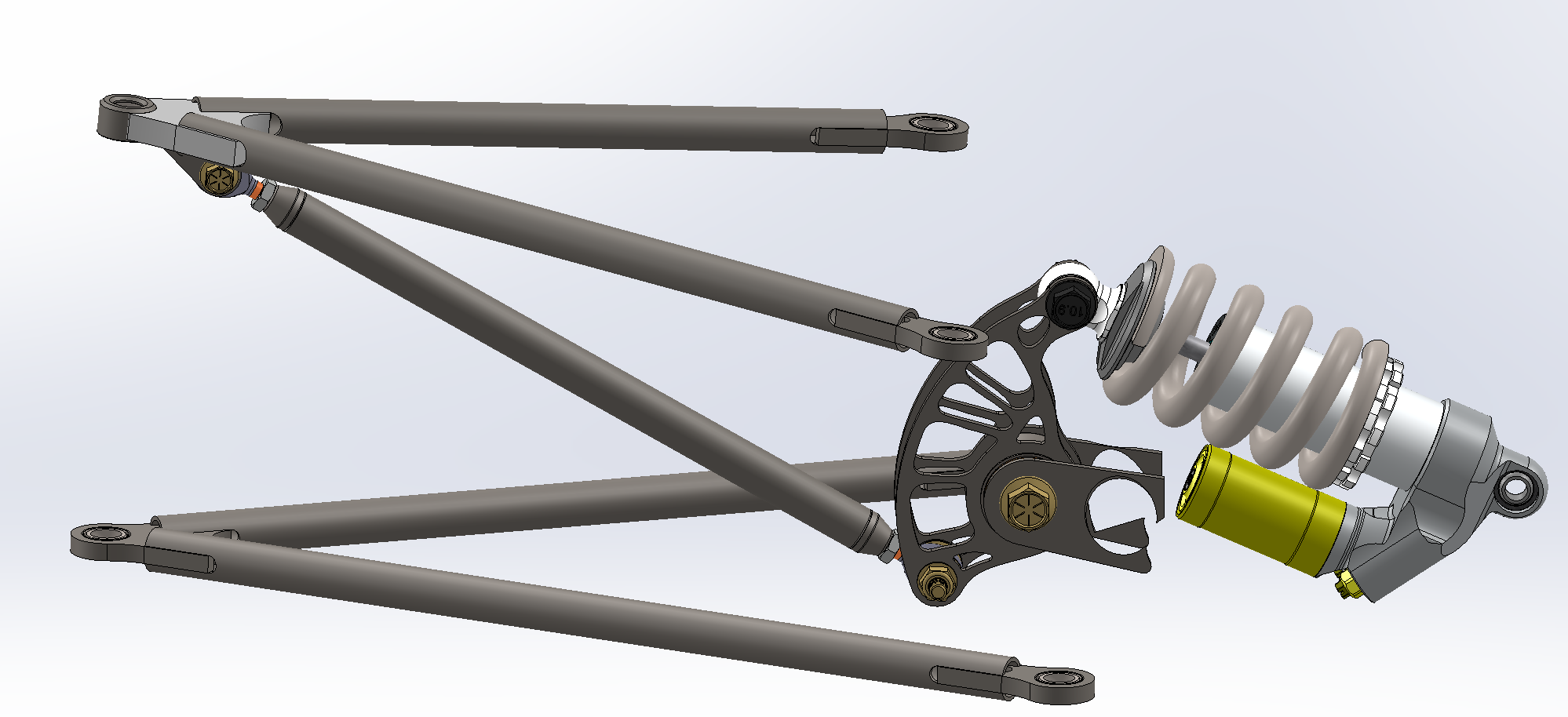

CB4 Front Control Arms with Push-rod

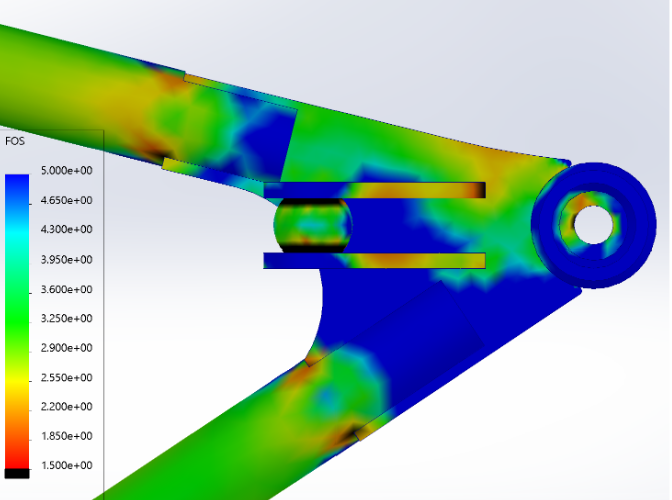

By making the change from pull rod to push rod mounting angle was now much larger and clearance to the inner barrel of the wheel would be compromised. In order to achieve this design the the mouting tabs would have to be moved farther inboard on the mouting plate. The problem this created was by doing so the force acting on the road through the push rod to the chassis was now also farther inboard putting the control arms in bending. The unequal length double wishbone control arm design ideally only experiences forces of tension and compression . However with the push rod mounting being farther inboard the moment of forces on the mounting plate would be higher. This required a slightly thicker mounting plate, slightly larger OD and tube thickness for the control arm tubes.

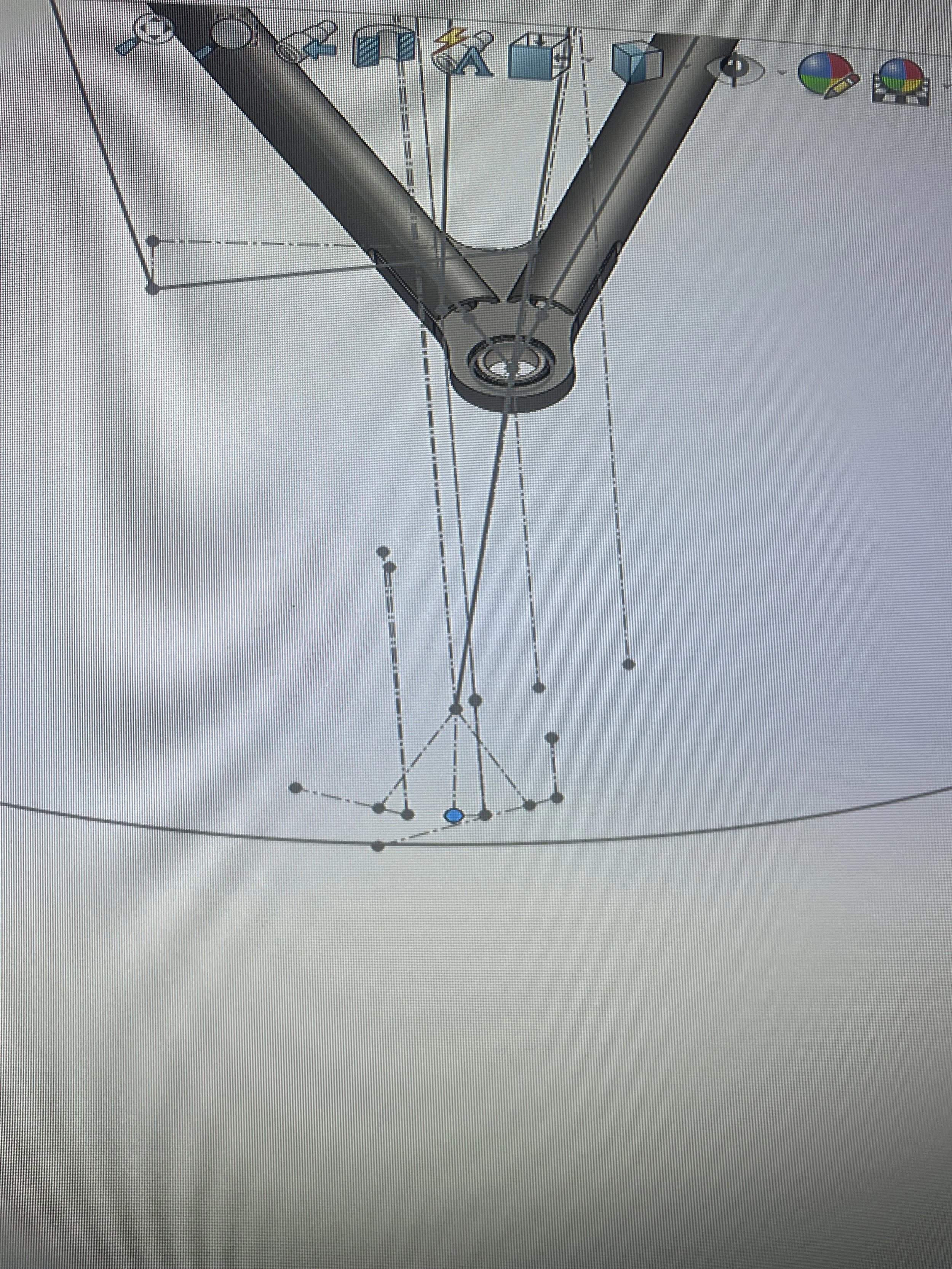

Hand sketch of the side view of front control arms. Comparing mounting place for the damper.

2023 Formula SAE Competiton:

At the 2023 Formula SAE Competition in Michigan we arrived with a car that had full completed and thoroughly tested prior to arriving in Michigan which was a first for the team. As a team we had success after success with very few set backs. While at Competition I was in charge of ensuring the car was properly set up was ready for the events. With the amount of time I had spent building and tearing the car apart then rebuilding during the spring I was one the 4 team members that would enter the event space allowing me to do final once overs and minor tunes according to driver feedback.

The team ended setting many team records with being only the second team out of Static Technical Inspection and passing Dynamic Tech for the first time since the had been founded again in 2016. And to cap it all off we completed endurance and placed 20th overall in competition which was the best in school history.

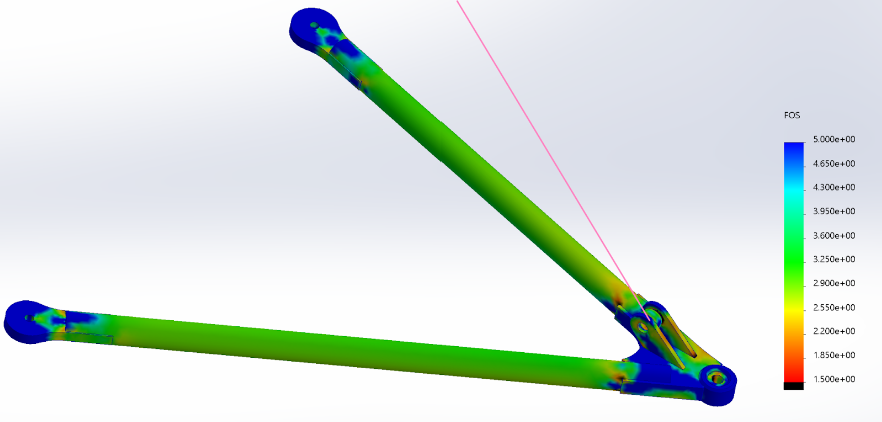

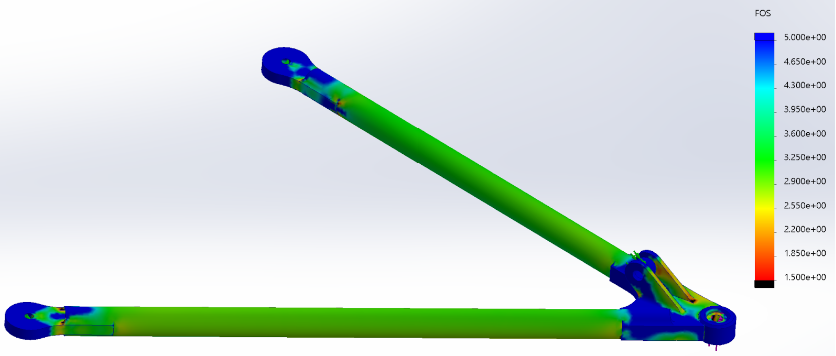

Design Analysis

For the analysis of the control arms, I did hand calculations for buckling as well as Finite Element Analysis for our 6 different load cases. The 6 load cases for the control arms are hard acceleration, hard braking, inside cornering, outside cornering, combined, and rolling backward. The forces and direction of the forces are calculated by a code that the team uses that takes the maximum force that the tire can create for the six different load cases and makes vectors that can be solved like a statics problem. This is done by having the tire contact patch be the origin (0,0,0) and then creating vectors to all the coordinates of the bearings where they will feel the force the tires are exerting on the car. this can then be solved in our code and give the force as well as the direction the force will be exerted.